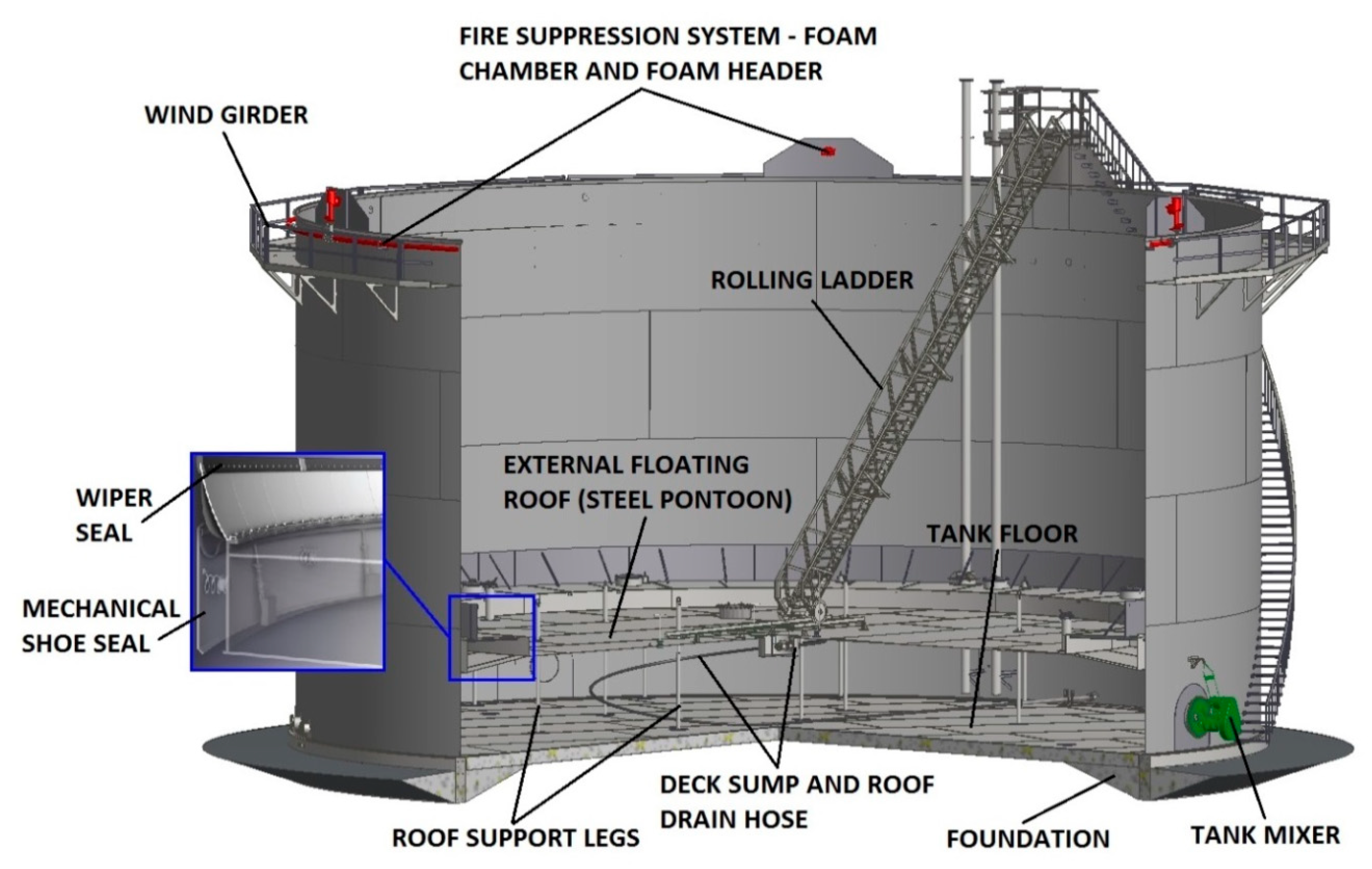

Adequate draining of this rain water is a very important aspect of safe and reliable operation of storage tanks with external floating roofs.

External floating roof tank drain system.

With the correct material selection it is suitable for all kind of stored products.

The primary drain for an external floating roof is required to be 3 inch minimum for tanks up to 120 feet in diame ter and 4 inch minimum for larger diameters.

Each drain line requires just a 500mm wide corridor to operate in between sump and shell nozzle.

An external floating roof tank is a storage tank commonly used to store large quantities of petroleum products such as crude oil or condensate.

Water buildup from rain and melting snow add a significant amount of weight on the floating roof system.

Draining rain water from an external floating roof is important to make sure the external floating roof will not build up too much water on top which could even cause sinking of the roof in the worst cases.

The matrix applied technologies drain system is easy to install in any tank.

The roof rises and falls with the liquid level in the tank.

Introduced in 1982 this system combines the flexibility of the various flexible hose pipe systems with the strength found in rigid pipe swivel joint systems.

Internal floating roof external floating roof seal al dome roof drain system floating suction oil skimmer tank fitting.

Especially in climates with high rainfall water can accumulate on the external floating roof.

We will provide installation drawings if you send us your drain data.

Floating roof storm water drainage systems are a vital component to the stability and operation of your external floating roof tank.

The hmt pivot master floating roof drain system is designed to innovatively provide a better solution to floating roof drainage problems.

In tanks above 60m diameter it is advisable for safety reasons to fit more than one drain.